Between The Lines 010: Zixiong Wei

An Additive Future with SCRY™ Lab

Words: Siân Toolan

Here at CONCEPTKICKS® we are notoriously obsessed with the what-ifs of footwear, from wildly inconceivable speculative design to the potential reimagining of the footwear industry at large. We sat down with one creative combining the two: Zixiong Wei, founder of SCRY™ Lab…

To Scry, by definition, is to see the future in a crystal ball and one would question if the secret of Zixiong Wei is one tucked away in his studio. His vision is to revolutionise and democratise the pillars of the footwear industry - from the way a product is designed, to how it is manufactured, distributed, and recycled - all via digitalisation. Whilst this week saw the release of the Heron Preston for Zellerfeld HERON01, Wei initiated his vision in early 2021, with SCRY™ Lab’s first pair of integrated additive manufacturing footwear, an entirely 3D printed shoe, available for purchase. He called it the Shuttle.

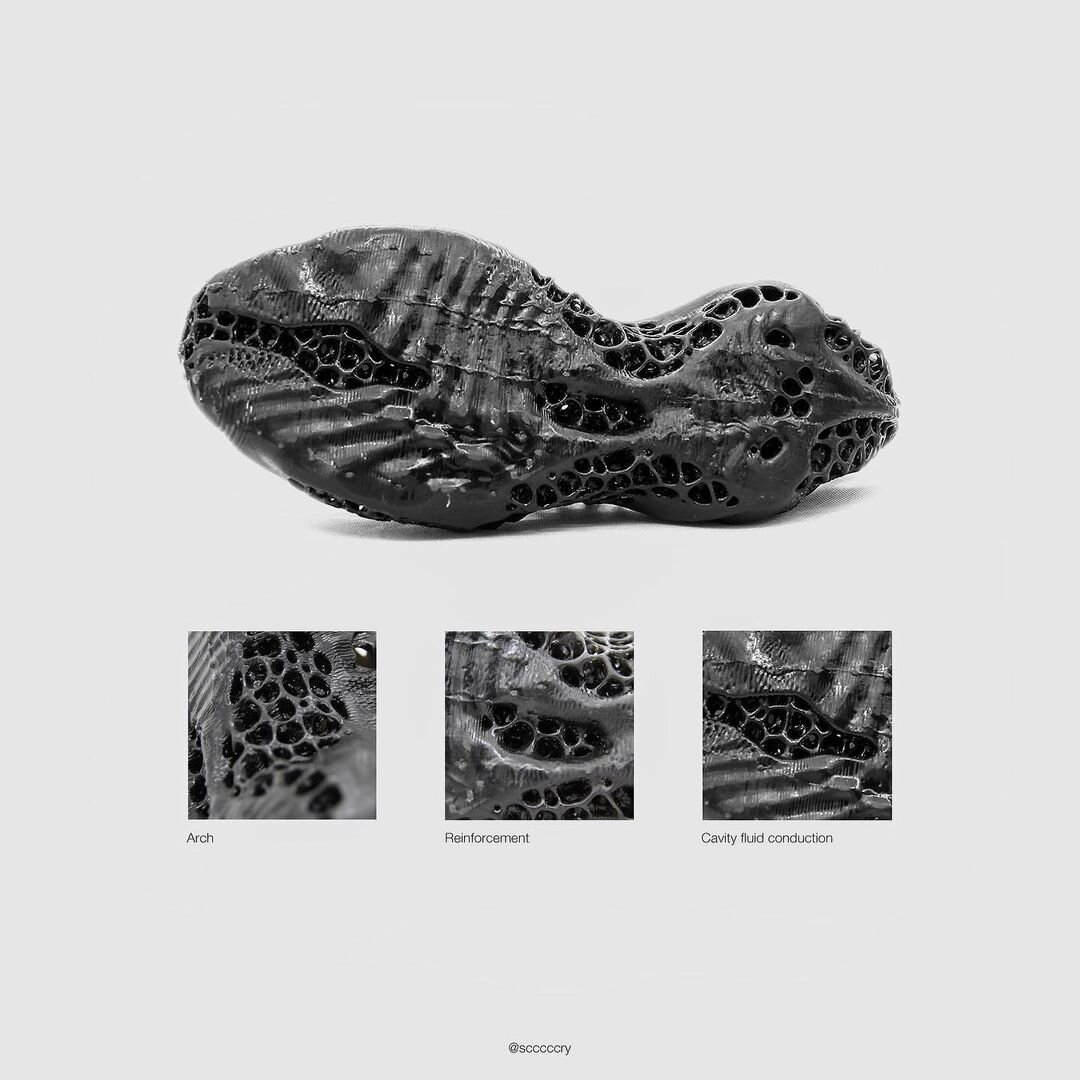

Since 2018, Wei has cultivated a devout Instagram following for his body of footwear concepts and penchant for technical innovation. It was only a matter of time before his sketches left the page. “I wanted to create a new footwear ecosystem where crazy, even non-marketable designs could come out, rather than stay on a drawing board forever, and the first step was to create SCRY”. Two years in the making, the SCRY Shuttle boasts an abstract but aerodynamic slip-on silhouette, that’s both extraterrestrial and organic in its design. Like the HERON01, the entire shoe uses an integrated printing process to eliminate any unnecessary material waste or a lengthy assembly line, and, printed in a single modified polymer material, it is completely recyclable. With a lattice structured midsole, the Shuttle features varying engineered structures for comfort, performance, and breathability whilst its digital design makes room for customisation. The SCRY Shuttle offers a “more innovative, sustainable, diverse and personalised future for the footwear industry”, in which design needn’t contend with the time, costs or waste of mould opening. Now, instead of predicting the future, SCRY™ Lab is creating it.

3D technology isn’t exactly a new phenomenon in footwear, we’ve seen leading brands dip their toe into the field, from cost-effective prototyping to the printed textile uppers of Nike’s Flyknit or the soles of the Adidas Futurecraft Runners. While we’ve witnessed some excellent design and progress in the application of this technology, few have set out to impact the industry quite like SCRY™ Lab. Wei’s exploration of integrative additive manufacturing has developed with it a model for his vision of footwear ecology; a model that challenges footwear’s high barriers of entry and manufacturing thresholds. The birth of the SCRY Shuttle was the birth of a Digital Embryo framework, an innovative structure of digital design and manufacturing with the potential to revolutionise the industry.

SCRY™ Lab’s Digital Embryo, simply put, “is a framework in which digitalisation runs through all processes”. A digital model used for printing and manufacturing shoes can also be used for augmented reality (AR) display, the circulation of virtual assets, private customisation, and even participation in computer-generated imagery (CGI). A digital version of a shoe can be released before it’s ever printed, and consumers can experience a fitting in real-time, all through the structure of the Digital Embryo. Indeed, each purchase comes with an exclusive ID card as a virtual wearing medium, with an AR asset activated via SCRY’s official Instagram filter. Conversely, Wei explains, “the reverse digitalisation of real printed materials can make online rendering more realistic, and truly achieve the perfect unification of the virtual and the real”. The SCRY Shuttle reveals the ability to connect the data of all digital-related technologies to create a seamless flow between design and manufacturing. It’s an undeniably complex system, in which every component needs to be perfectly unified for it to be actualised, but Wei believes “digitalisation itself not only represents freedom and directness but also represents the underlying logic of design and manufacturing automation”.

The Digital Embryo is aptly named, as a network of intricate systems, wired together into a fully functioning body, that can connect with new interfaces or rapidly evolve. The high design iteration capability of this framework is demonstrated in SCRY™ Lab’s second commercial product SCRY Core, released in June of this year. If Shuttle is an evolved, living creature, Core is its skeleton. SCRY Core retroactively simplifies Shuttle’s design into a sleek, space-age shoe that reveals the inner workings of additive manufacturing with pockets of visible latticing, and prioritises functionality with a woven tape strap and metal buckle closure. Established as a laboratory, opposed to a brand, SCRY™ Lab is invested in research and development, rather than an aesthetic sensibility. Like a laboratory, “we want to stay neutral, constantly exploring different things, open to all new visual styles” says its founder. In September, SCRY Core was updated with Core Boots Accessories, a zip-up sock-like sheepskin leather attachment that transformed the slip-on shape into a boot. This approach doubles down on the evolutionary ideology of the brand, adapting its models inside and outside of the Digital Embryo framework, to extend the versatility, wearability, and life of its product.

WGSN, the crystal ball of consumer trends, forecasts that the aftermath of the pandemic will see growing consumer expectations for practicality, multi-functionality and longevity in their purchases, as well designs that are sustainable and transparent in their supply chain. Zixiong Wei’s integration of digitalisation and additive manufacturing could deliver these expectations across the footwear sector. SCRY Lab’s on-demand manufacturing capabilities can produce new and interesting designs in small quantities at a vast speed and this allows his business to grow sustainably and organically. Wei explains that from the offset he had one goal - to build the future footwear ecology in this way.

The footwear industry is still the most labour-intensive industry, with extremely high manufacturing thresholds, especially for slightly more complex shoes. This, Wei believes, prevents a lot of good design from coming to market as “young and excellent designers are often unable to make a pair of shoes on their own and this is detrimental to the diversification of the footwear industry“. SCRY™ Lab is actively pushing the status quo of what a small business can do as the digital embryo frees the restrictions of classic footwear design, initiates manufacturing based on demand, with sustainable development and a lower threshold for shoemaking. This would enable smaller brands to break into the market and, in turn, deliver a diverse range of products and a democratic, decentralised industry. Wei would like to diversify the ecology so much so that “the power of design and manufacturing gradually devolves to consumers” and he is currently working on the technology for both a SCRY design support and manufacturing support platform.

With innovation at the core of the company and a future sight like no other, there’s a lot yet to be seen from Zixiong Wei and SCRY™ Lab. We’ve just been teased with SCRY Neptune, an alienesque cowboy boot releasing in October, and a collaboration with one of fashion's most forward-thinking creators, Iris Van Herpen. With SCRY™ Lab the future of footwear is cheaper, cleaner, more accessible, diverse, and ultimately healthier for both the planet and people. All we can hope is that it doesn’t take too long for the industry to catch up.